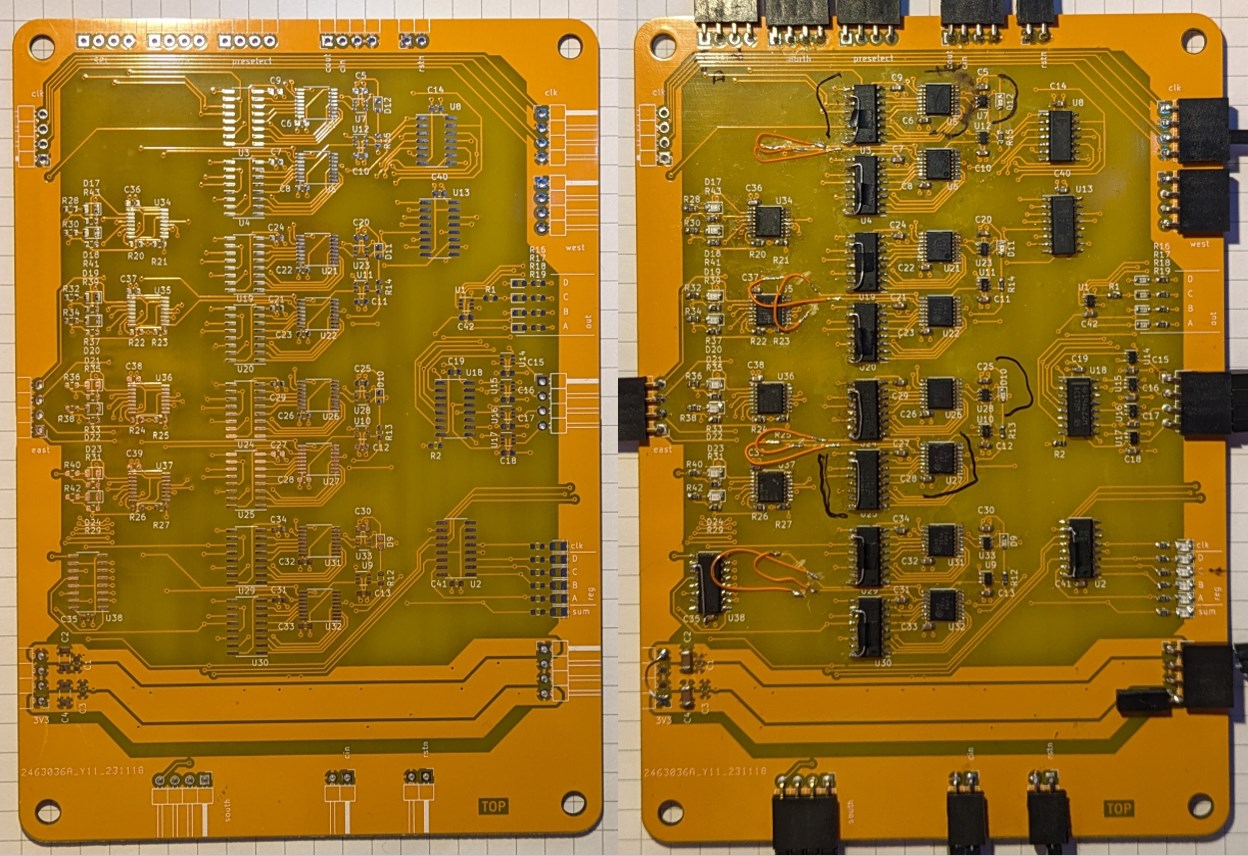

Fig 1: PCB before and after assembly and debugging.

Fig 1: PCB before and after assembly and debugging.

A month or so after sausageing around in KiCad I have some fresh PCBs on my desk ready for prototyping. (Not for the life of me! did I want to make this a 4-layer PCB even though we live in 2024 and there are virtually no good arguments against 4-layers anymore. anyways.) The boards look pretty. And yellow. Just like in the drawings I made.

In theory, theory and practice are the same. In practice, they are not.

Well, in theory my digital twin (in VHDL, see previous article) and whatever I assembled on the PCB are the same.

The first fuckup that was noticeable was the wrong polarity on the output enable (~OE) of the shift registers.

This condition made itself noticable by being a classic implementation of a WOM (write only memory).

I had to embark on a mission to attach a modwire on every single shift register ~OE pin after which all lights started flashing and blinking like a disco.

So I went ahead and implemented the 1-bit counter (inverter) on the PCB. It worked!

The next logical thing to test is a 2-bit counter which I immediately uploaded and saw it blink the wrong way.

I went back to the VHDL model but it did not spark joy to build another testbench just to figure out the wrong bit.

Now here is a different approach: Test your digital design with an Arduino as the testbench.

Because I figured,

- a) I am quicker with breadboard wires and with C-code on an Arduino (vs. generating incremental stimuli data in Python and write a new VHDL testbench)

- b) the error(s) are more likely due to bad soldering on the PCB anyways

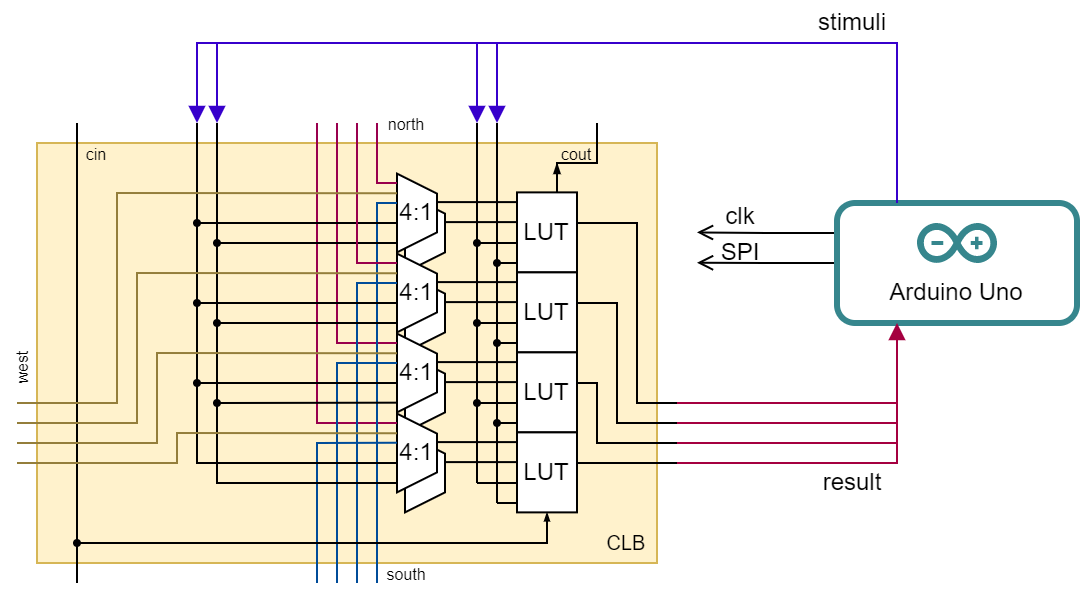

What I came up with is shown in Fig. 2.

Fig 2: Testbench approach with an Arduino Uno to provide bitstream, clocking and stimuli data and read back any results.

Fig 2: Testbench approach with an Arduino Uno to provide bitstream, clocking and stimuli data and read back any results.

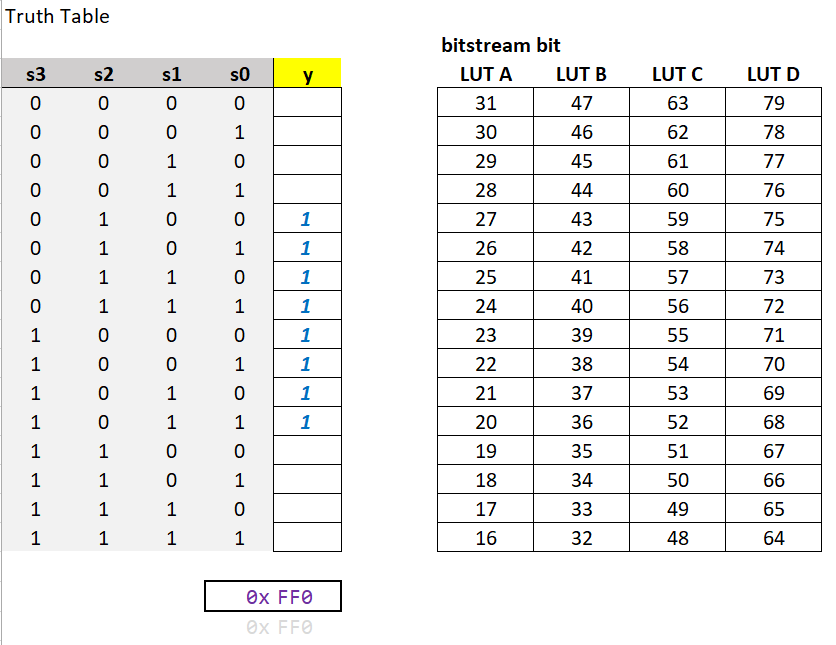

Thechnically, I had documented the bitstream before in an excel sheet.

Because I absolutely needed this for when I want to set bits according to a truth table.

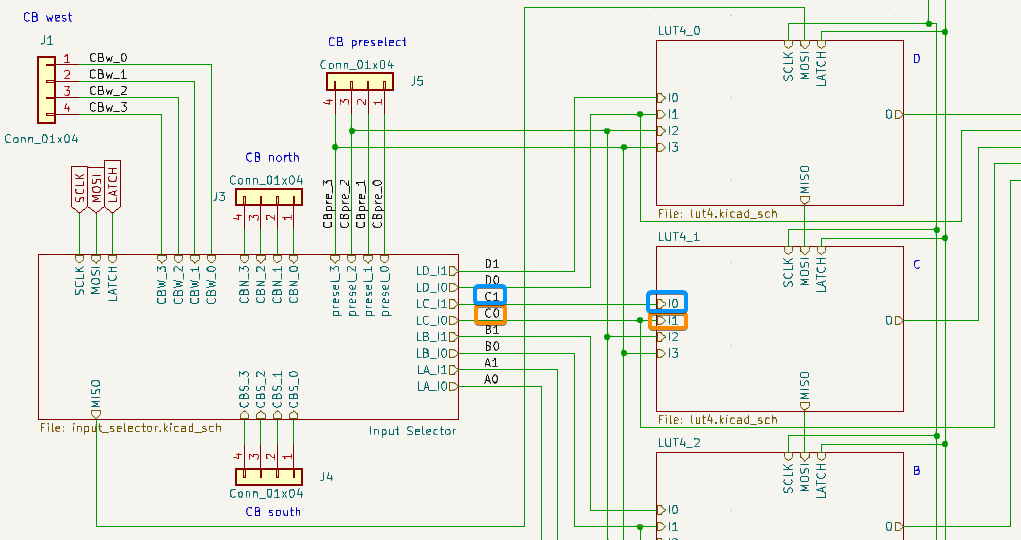

Let’s see how the second bit should behave when implemented in LUT.

Note that the counter input bits are in reversed order - bit 0 is marked m and bit 1 is marked s2.

Since we are now using LUT_B this table tells me that I need to set the bits 36 to 43.

Fig 3: Truth table for bit[1] of a counter.

Fig 3: Truth table for bit[1] of a counter.

Well, here is where it blinked the wrong way. So I coded an Arduino script which does the following things:

for each LUT in LUTs:

for each bit in conf_bit:

program_bitstream(bit)

for each stim in input_vector:

write(stim)

clock_pulse()

read(result)

if(result)

print("1")

else

print(".")

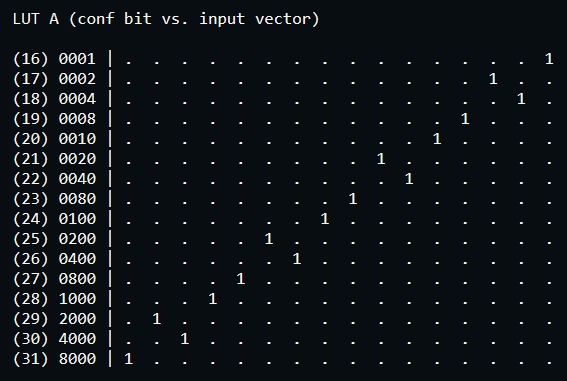

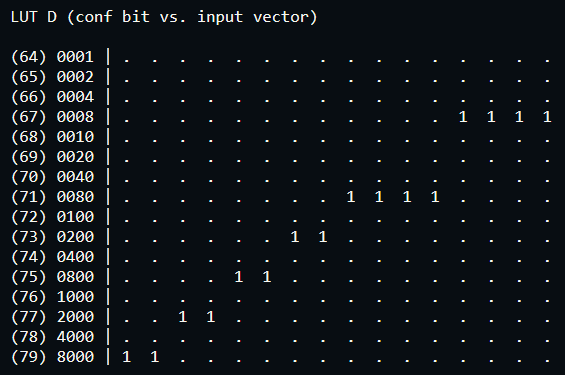

This will print a matrix of how the LUT behave to all input stimuli given all single bit configurations. The output looked a bit like this:

Fig 4: Measured LUT output behaviour for LUT_A.

Fig 4: Measured LUT output behaviour for LUT_A.

Now each configuration bit should act upon exactly one single input vector to produce a 1 at the output. What we see here is some type of bit flip. And promptly, if I check back with the KiCad schematics, I produced a bug all by myself. The VHDL simulation would not have caught this.

Fig 5: Concept view of the proposed CLB.

Fig 5: Concept view of the proposed CLB.

Another journey into modwire-land later, we have this problem sorted. However, there was more trouble.

Fig 4: Measured LUT output behaviour for LUT_D.

Fig 4: Measured LUT output behaviour for LUT_D.

I’ll spare you the details (because I don’t actually know them myself) but this problem was caused by several bad (cold) solder connections. After resoldering a bit of everything, it worked and produced a clean diagonal line of 1’s. Now I can use the above truth table in Excel to create the remaining LUT functions of an entire 4-bit counter. And it works!!

Fig 5: 4 bits counting ahead…

Fig 5: 4 bits counting ahead…

We end with a first conclusion: Yes, it is possible to waste dozzens of 7400-family ICs to recreate half of a single 7400-family IC. I am thrilled to expand this project further.